fusilier1944

Company Commander

This is a new vehicle I'm working on. I've done the command car previously. Don't think that one was posted here but it is on the Sixth Division (Steyr 1500 A/2 Kommandeurwagen CLICK HERE)

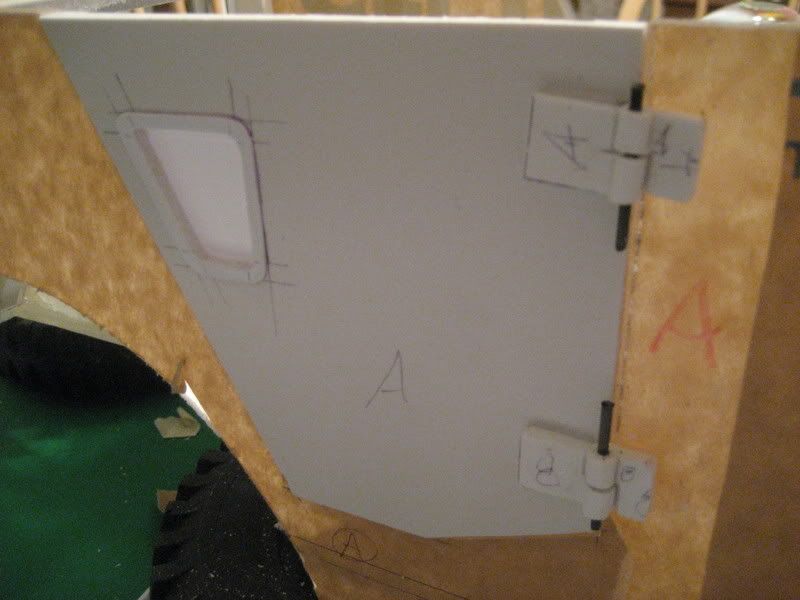

This is the regular troop truck version. So far I'm building it out of 3/16" and 1/4" Acrylic/plexiglas. I plan to use wood to do the frame underneath. Detail work will be with plexi, styrene and PVC. I'm going to mount either 6" lawnmower wheels or some DeSimone GI truck wheels that I have. I'm going to look for some PVC pipe end caps to use as replacement hubs in the wheels. On the command car I used sculpey to make forms to cast wheel hubs with resin and I'm not doing that again.

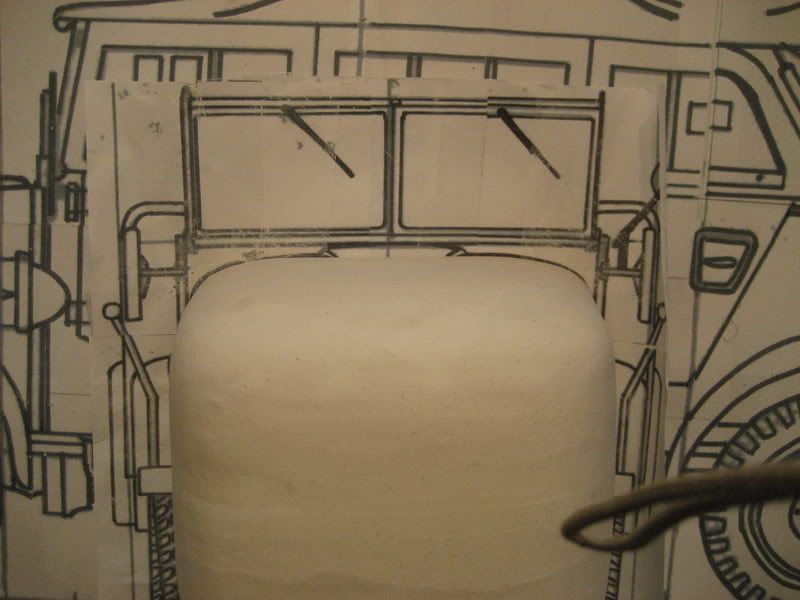

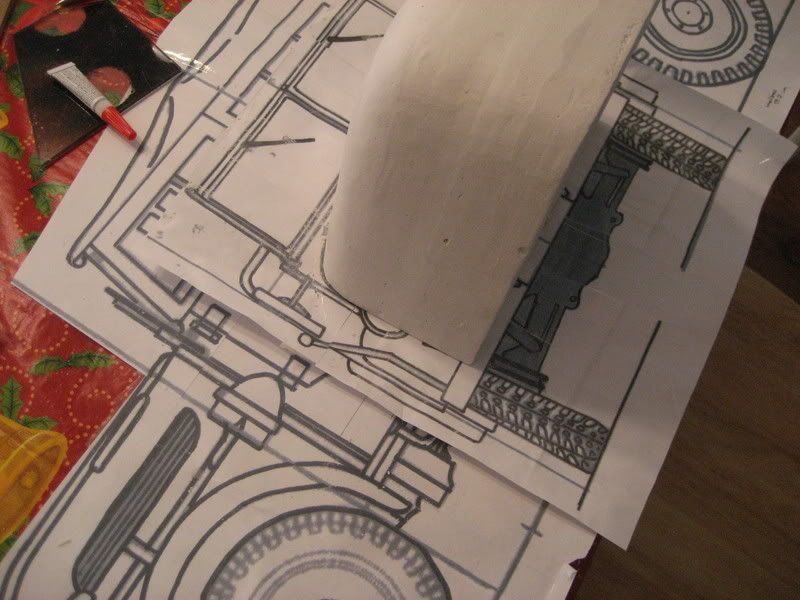

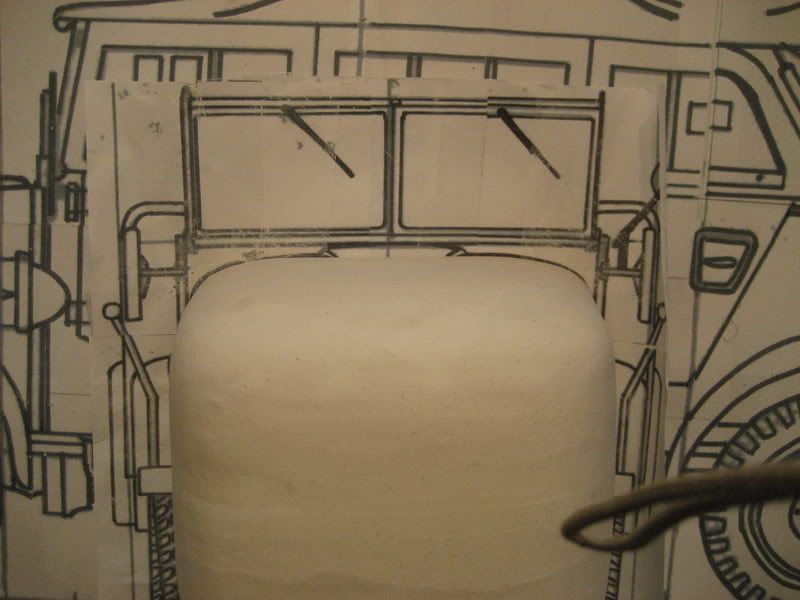

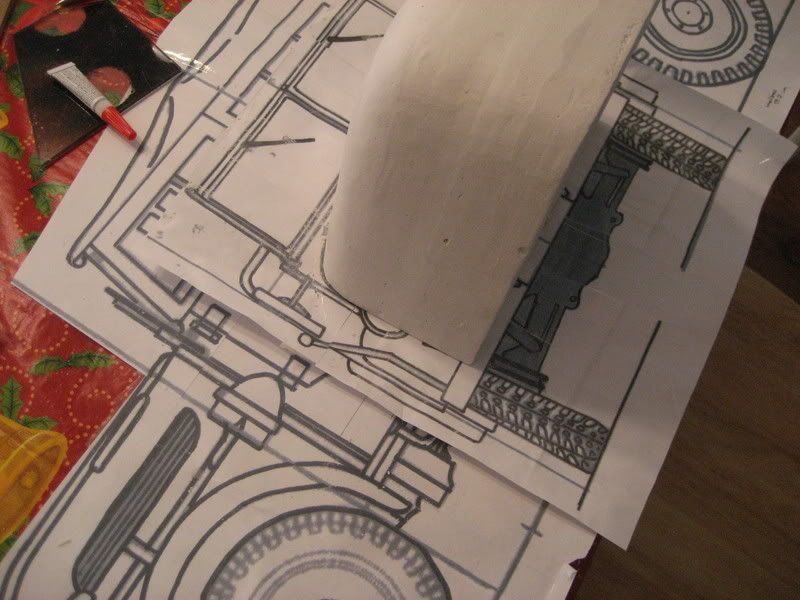

The big pieces of this one are the hood and the front fenders. Previously I built framed fenders and sanded the hood down from layered plastic. This time I'm going to try fiberglass. It will be the second time I've worked with fiberglass but the first time I've done it alone. I plan to mold it over plaster of paris forms. The big white thing on the front end is the form for the hood. I think I need to remove some more material to account for the stuff that will be formed over it. Hopefully this will go easier and make much less of a mess. I haven't gotten to the fender forms and I don't look forward to making them symmetrical/mirror images of each other.

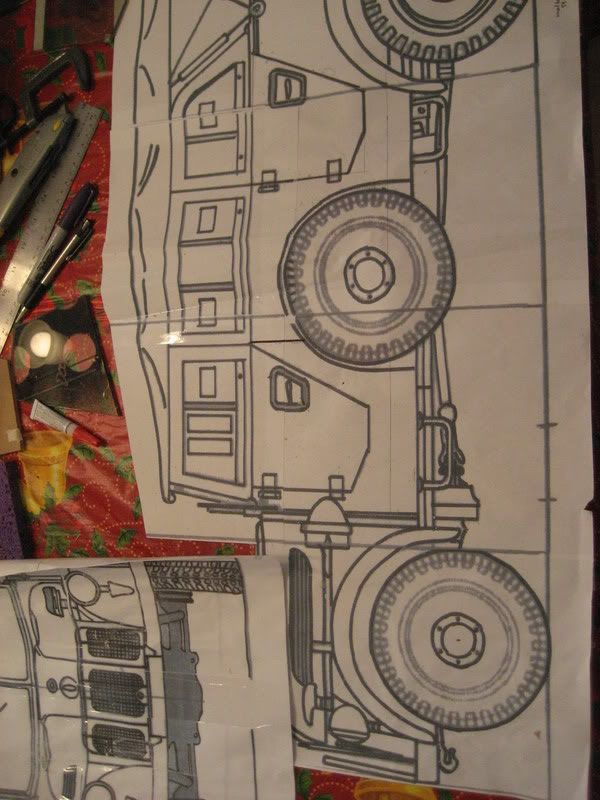

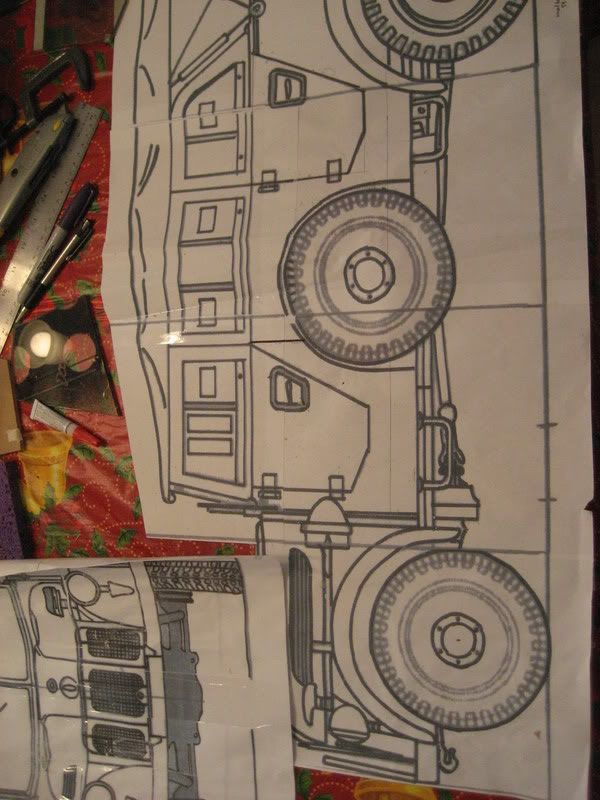

This is also the first time I blew up a multi-view drawing to work off of. One thing I learned is that it helps to have all the views be the same scale in the first place. I ended up wasting quite a bit of time before I realized my front and rear views were a different scale than my side view. I had to scale them three times; 1st to 1/35 scale then 400% of that (the largest my printer could do), refine the lines with a Sharpie marker, then scale to whatever % got them up to 1/6. Pain in the butt though a grid I drew on the paper helped me scale them nicely with each box on the grid becoming 1 page of paper. Here're some pics of the views and how I got the plaster block to shape working on the front view

This is the regular troop truck version. So far I'm building it out of 3/16" and 1/4" Acrylic/plexiglas. I plan to use wood to do the frame underneath. Detail work will be with plexi, styrene and PVC. I'm going to mount either 6" lawnmower wheels or some DeSimone GI truck wheels that I have. I'm going to look for some PVC pipe end caps to use as replacement hubs in the wheels. On the command car I used sculpey to make forms to cast wheel hubs with resin and I'm not doing that again.

The big pieces of this one are the hood and the front fenders. Previously I built framed fenders and sanded the hood down from layered plastic. This time I'm going to try fiberglass. It will be the second time I've worked with fiberglass but the first time I've done it alone. I plan to mold it over plaster of paris forms. The big white thing on the front end is the form for the hood. I think I need to remove some more material to account for the stuff that will be formed over it. Hopefully this will go easier and make much less of a mess. I haven't gotten to the fender forms and I don't look forward to making them symmetrical/mirror images of each other.

This is also the first time I blew up a multi-view drawing to work off of. One thing I learned is that it helps to have all the views be the same scale in the first place. I ended up wasting quite a bit of time before I realized my front and rear views were a different scale than my side view. I had to scale them three times; 1st to 1/35 scale then 400% of that (the largest my printer could do), refine the lines with a Sharpie marker, then scale to whatever % got them up to 1/6. Pain in the butt though a grid I drew on the paper helped me scale them nicely with each box on the grid becoming 1 page of paper. Here're some pics of the views and how I got the plaster block to shape working on the front view

so far its looking good.

so far its looking good.

I never had luck scaling up smaller drawings with out 1:1 reference and lots and lots of wasted paper. LOL I will be very interested in seeing your fiberglass work I never liked working with it myself because it really bothers me I can't work with fiberglass insulation with out itching for days.

I never had luck scaling up smaller drawings with out 1:1 reference and lots and lots of wasted paper. LOL I will be very interested in seeing your fiberglass work I never liked working with it myself because it really bothers me I can't work with fiberglass insulation with out itching for days.