gatuko

Marksman

Hi to all

I want to present you my last creation...

Sorry for my English... this is an automatic translation, I dont know enough english to explain to you properly... if you do not understand something, please let me know... and I try to tell to you better...

Thanks in advance...

After several months of work, effort, learning new technologies, headaches and a lot of joy, now is the day I've waited and how much has been slow in coming.

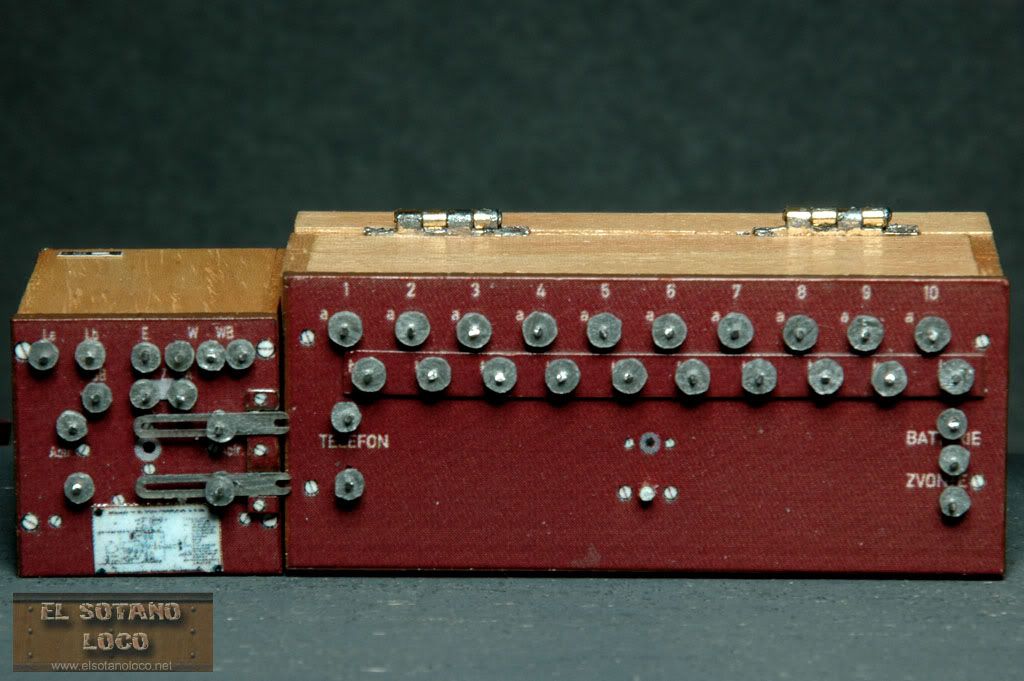

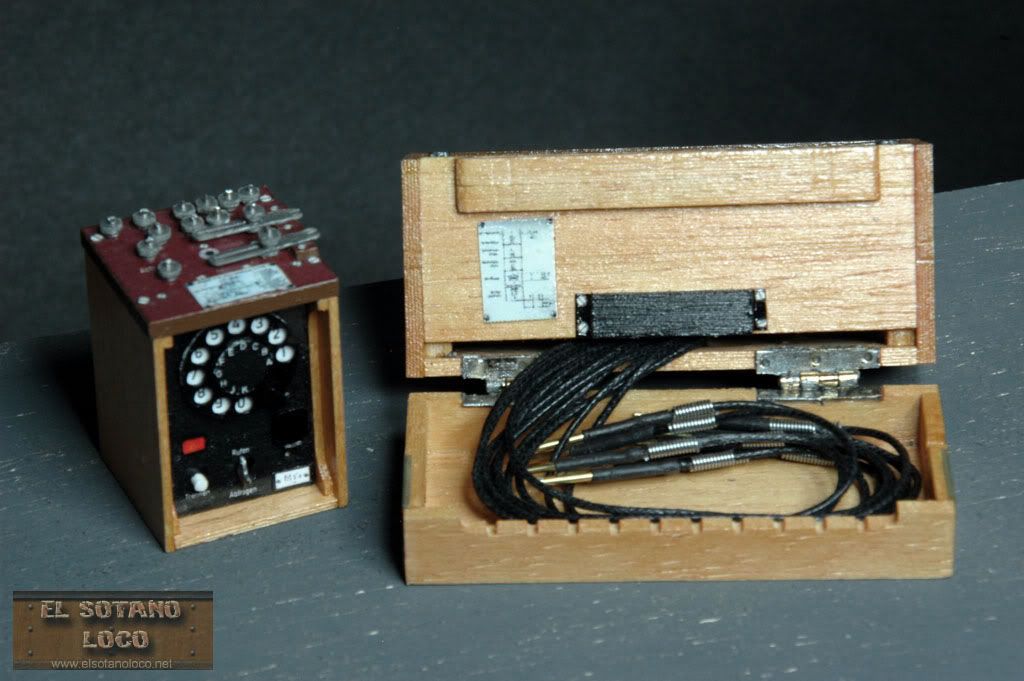

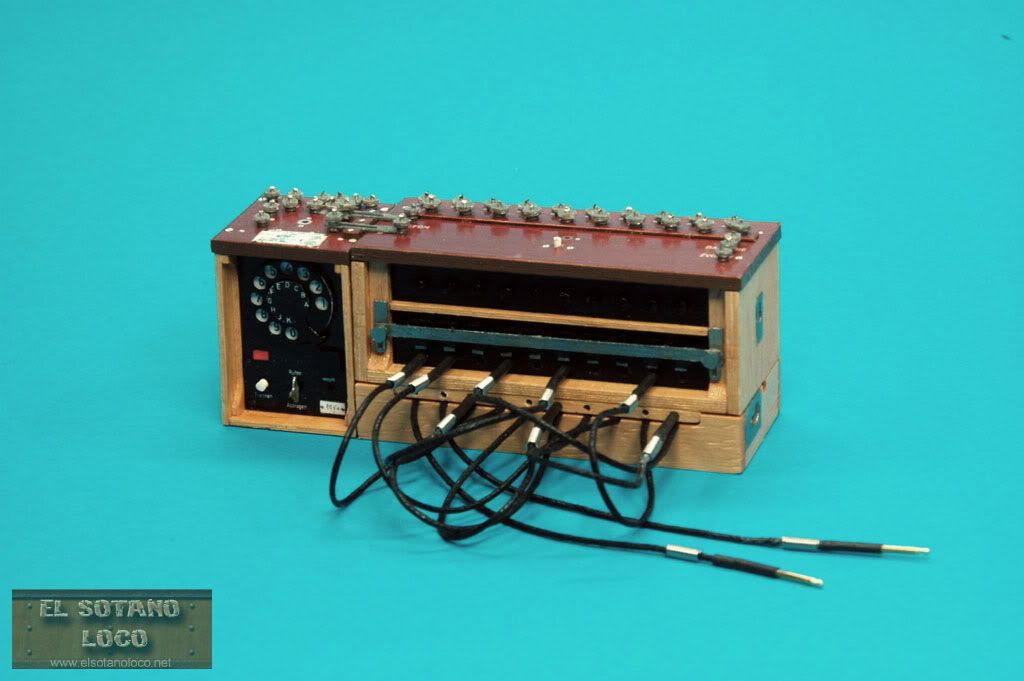

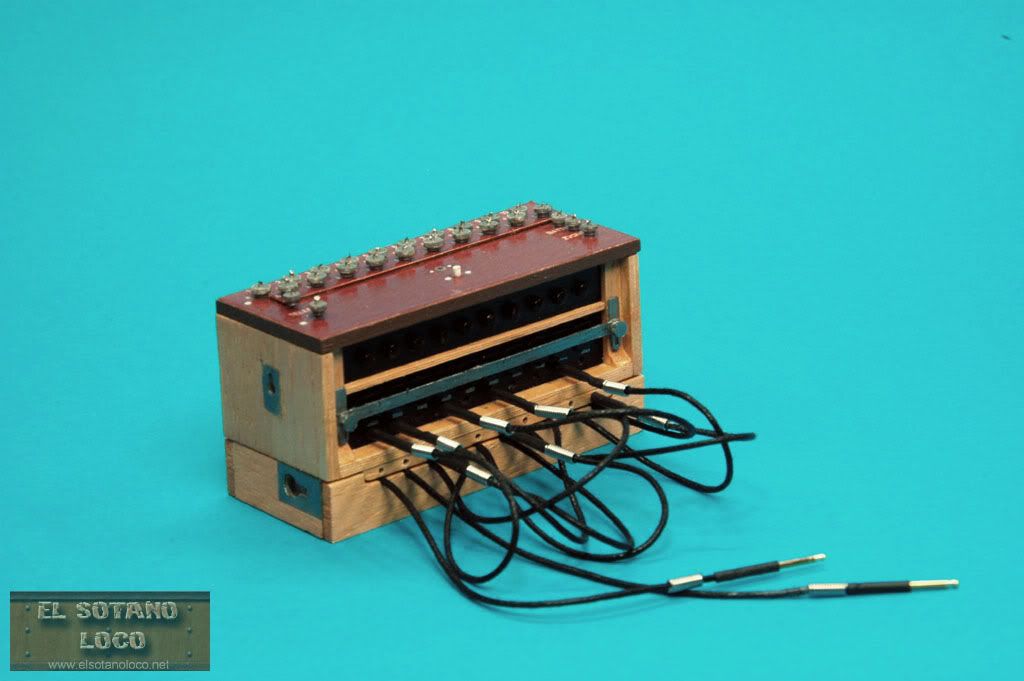

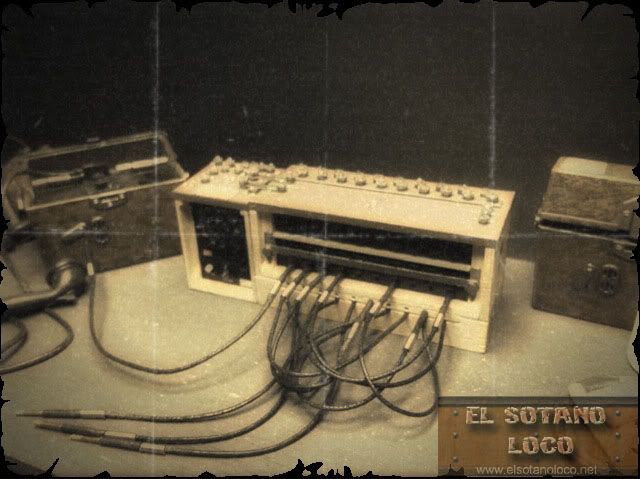

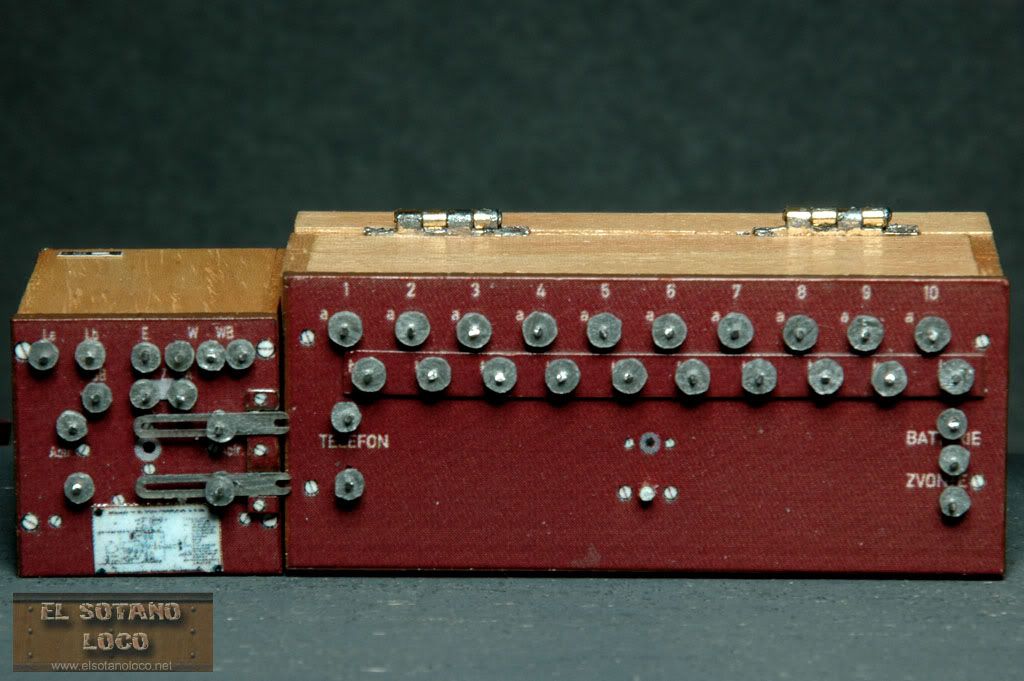

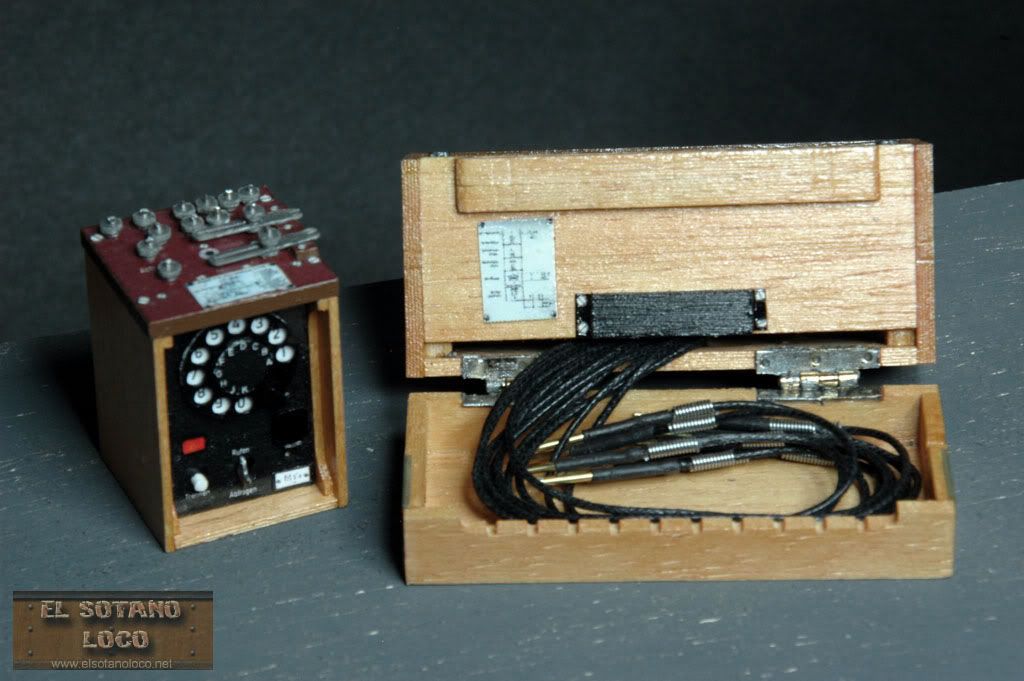

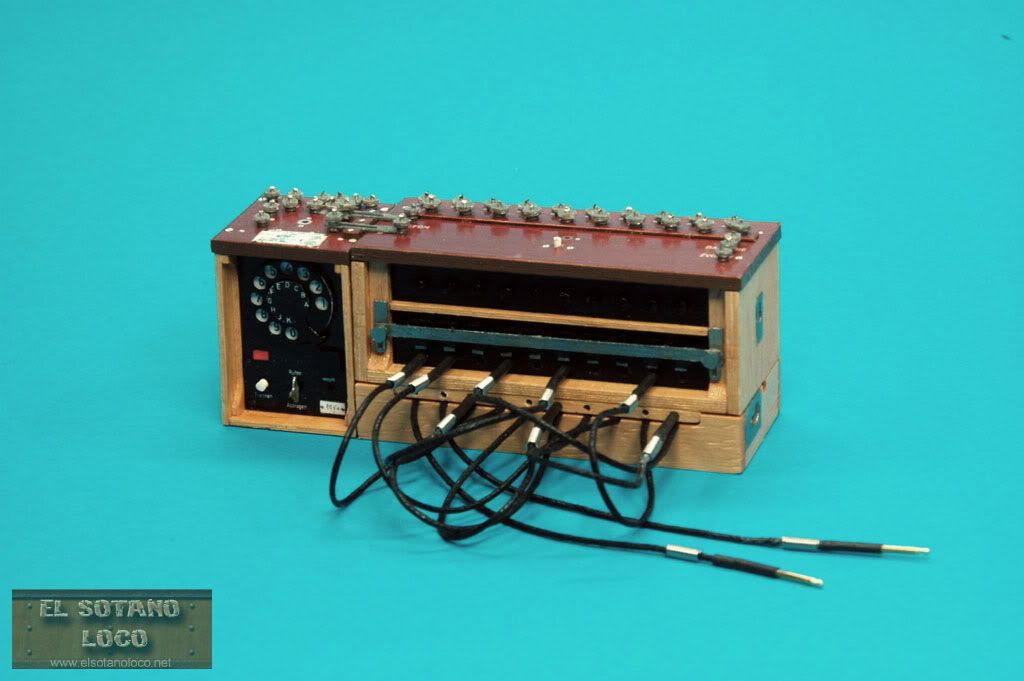

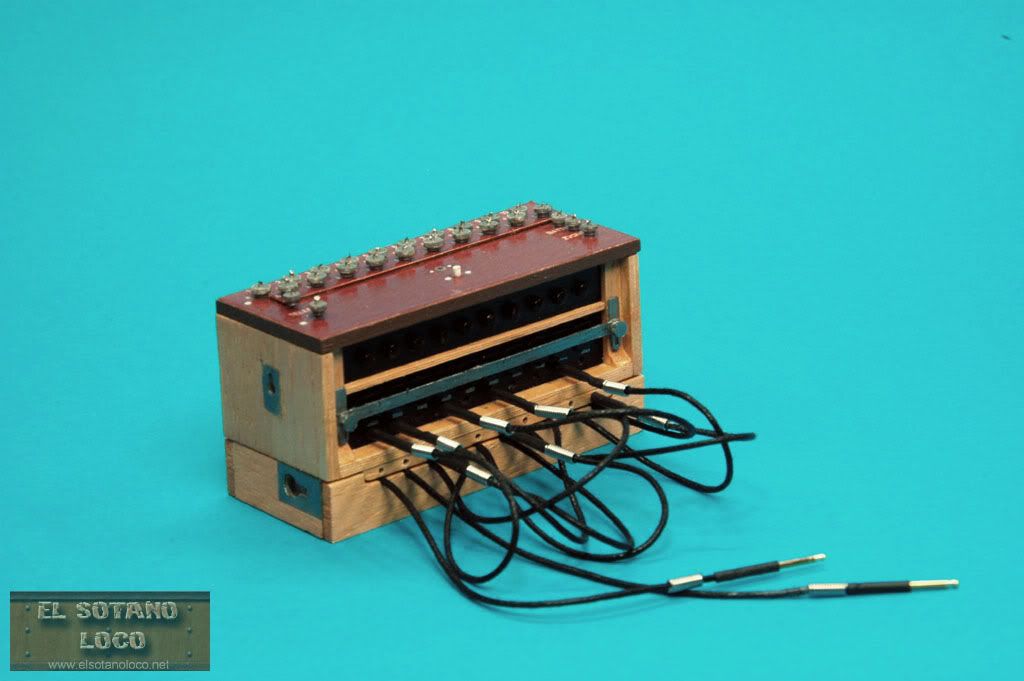

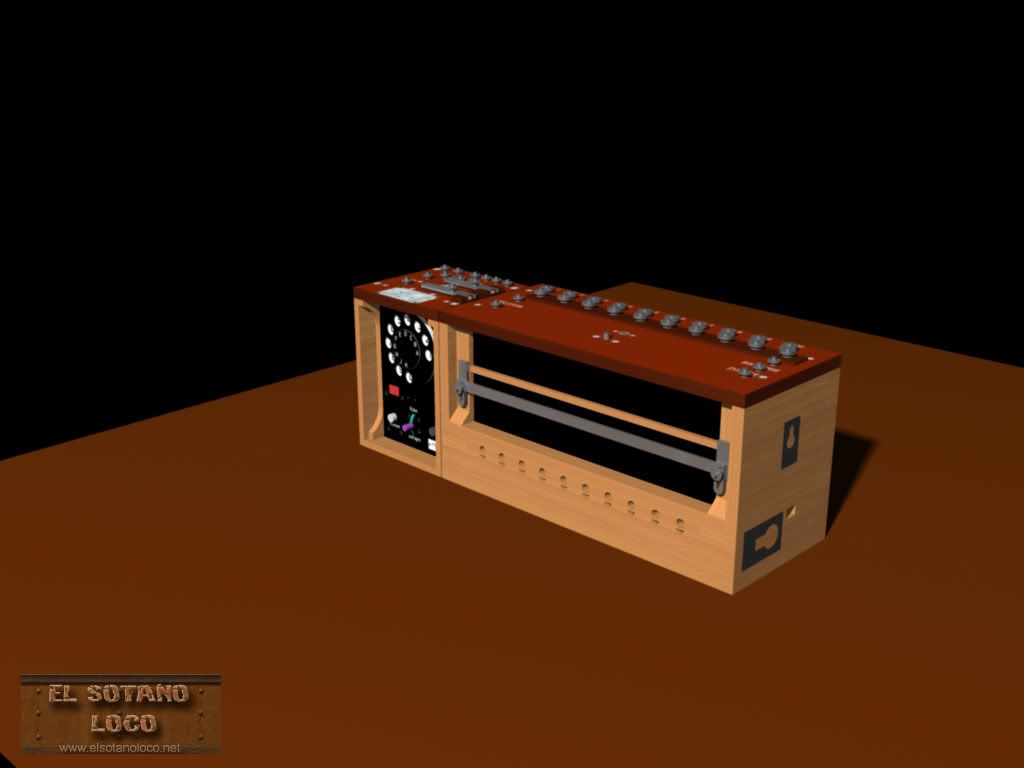

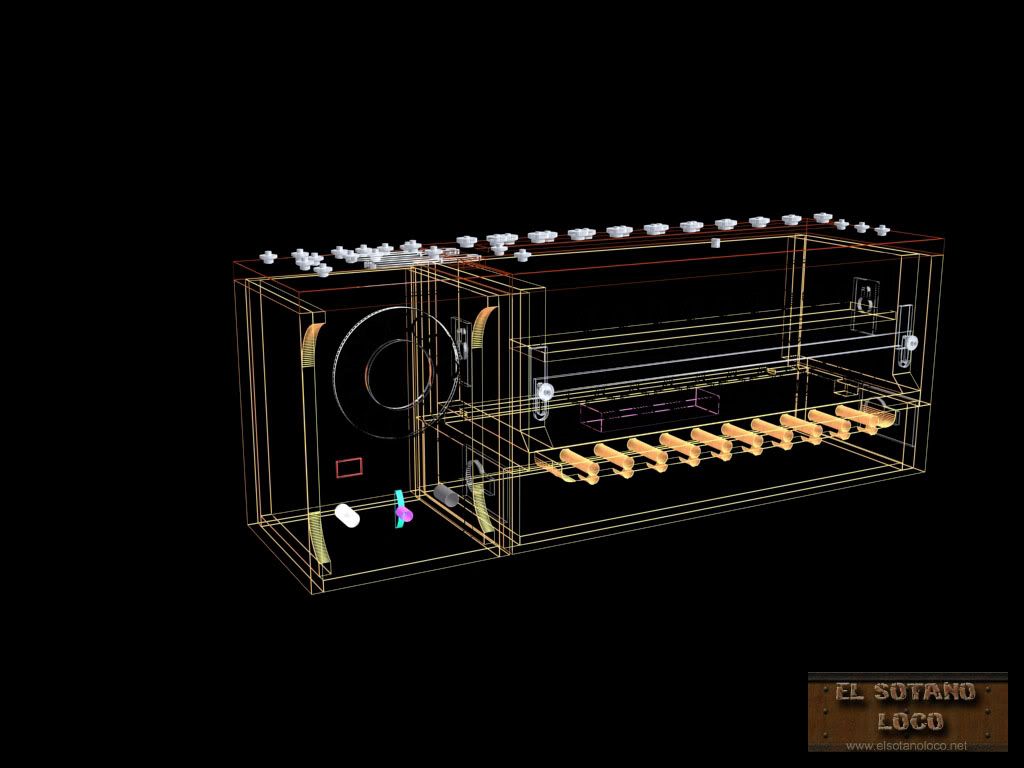

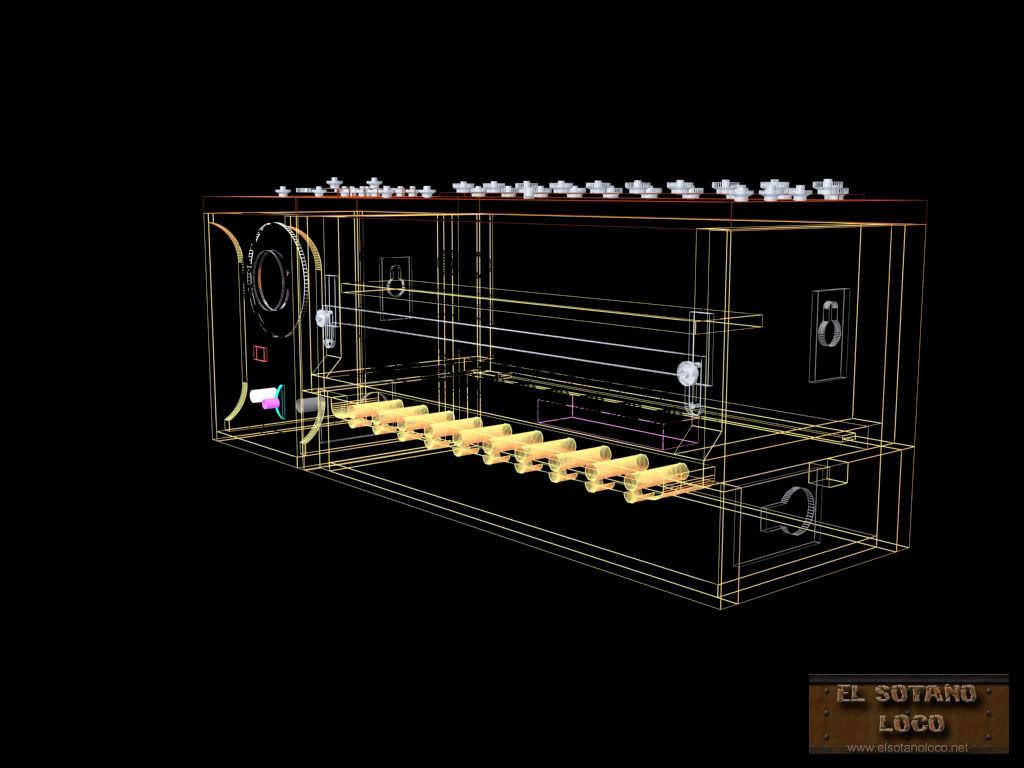

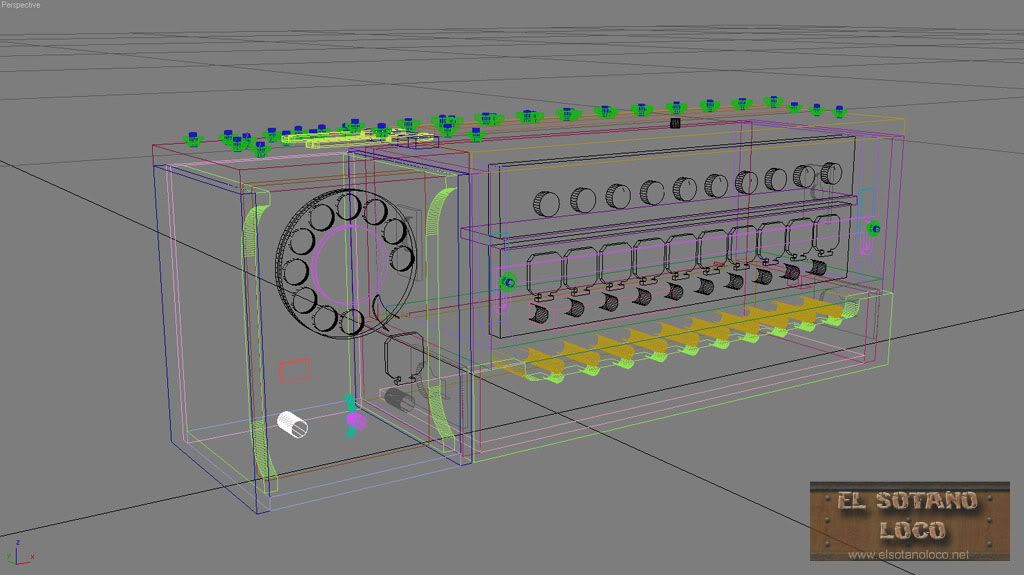

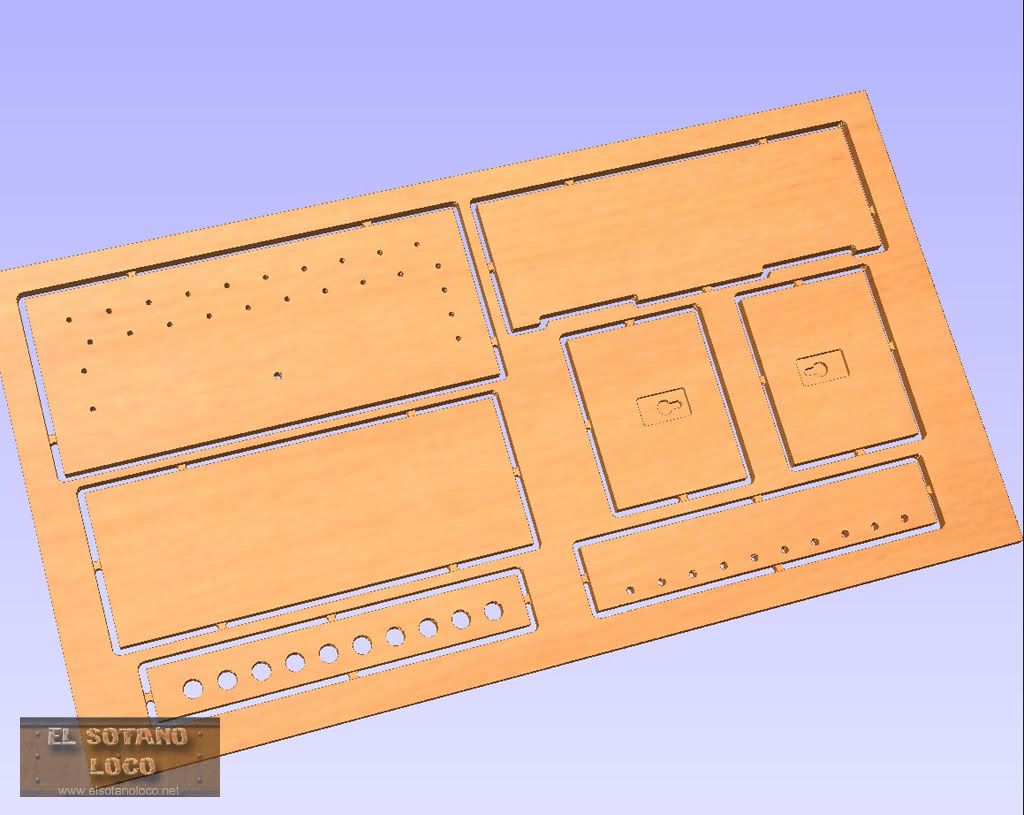

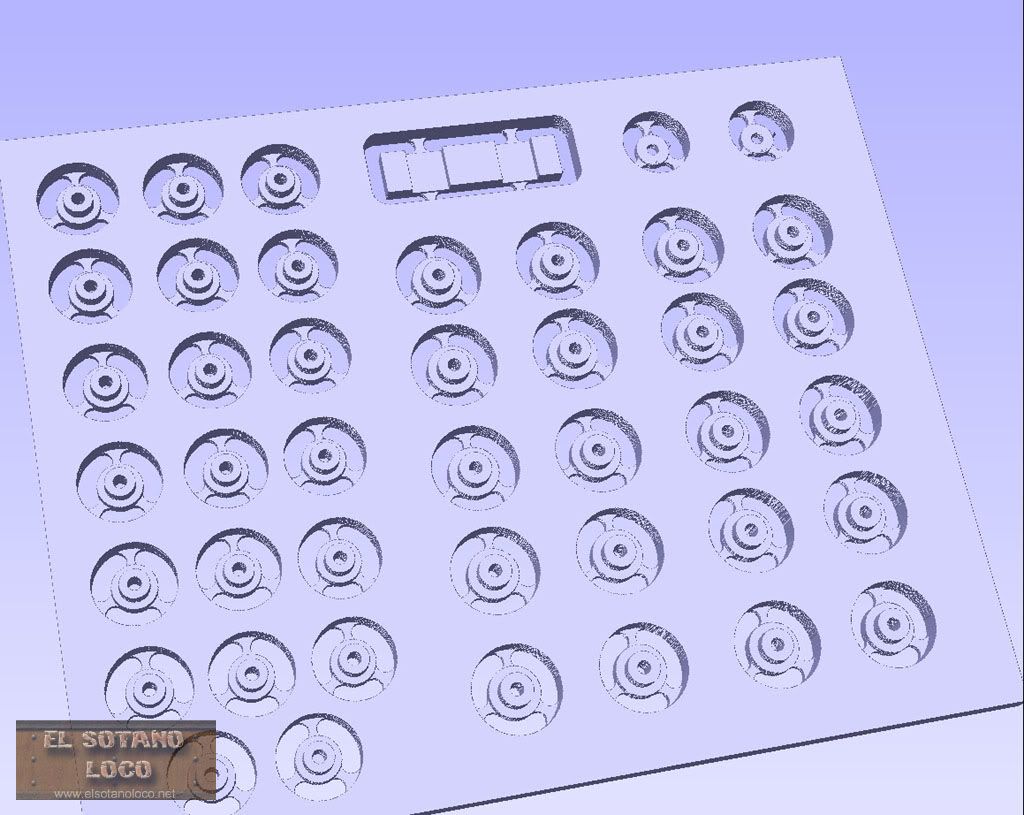

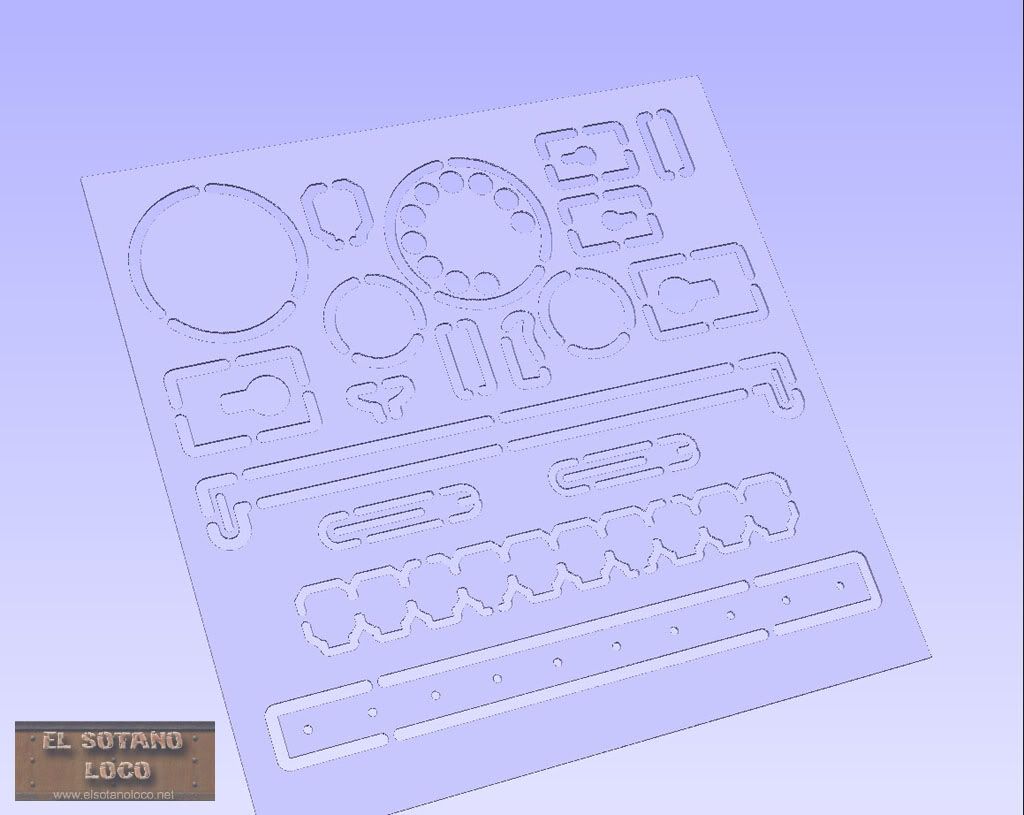

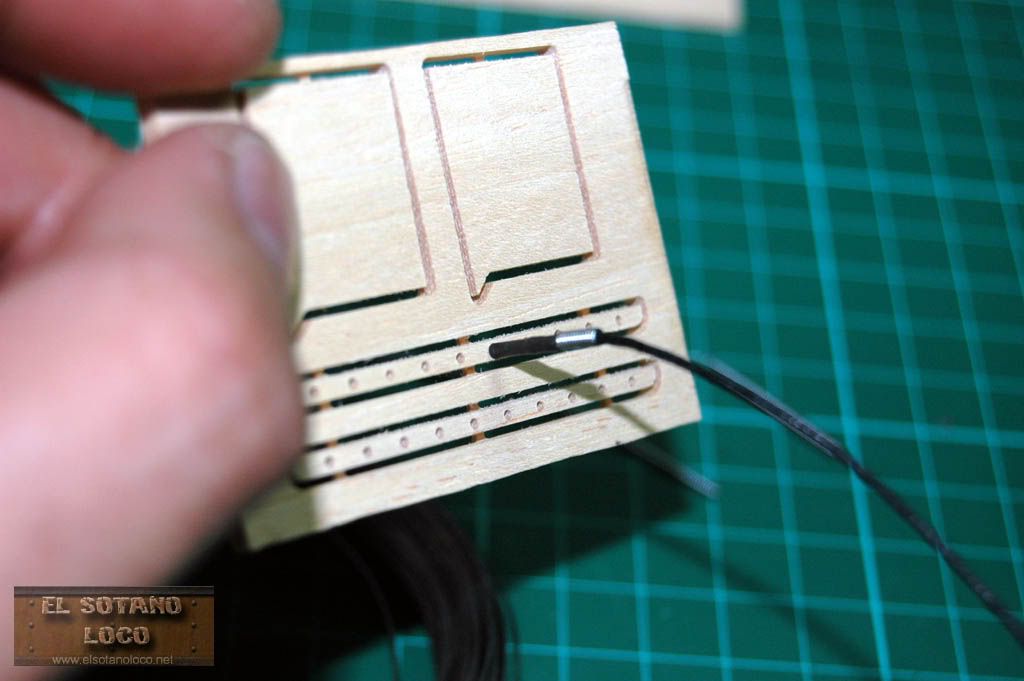

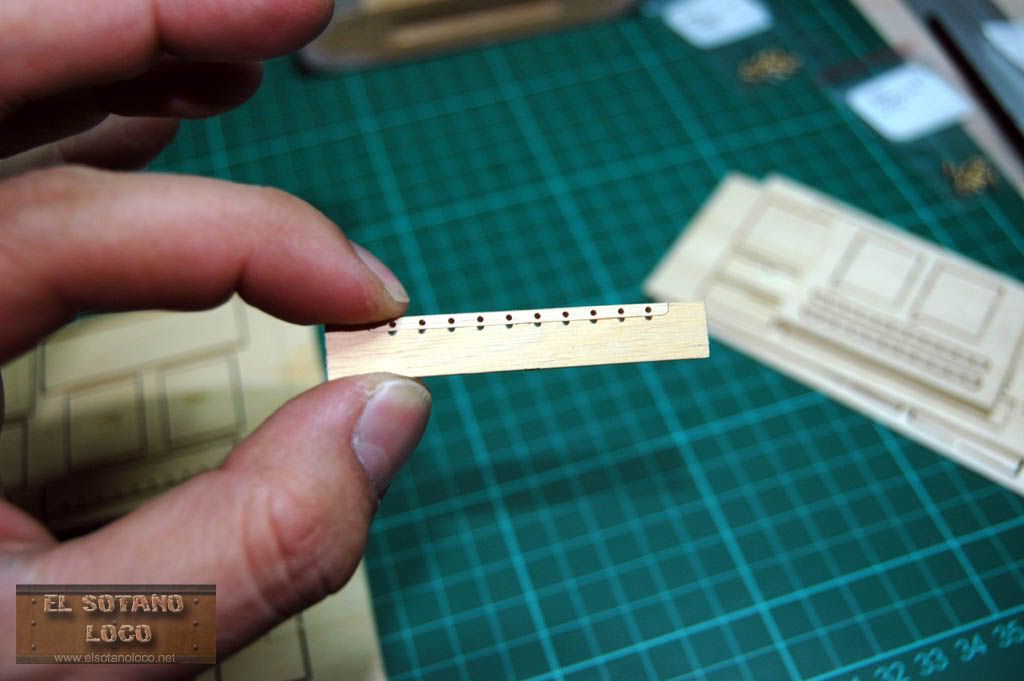

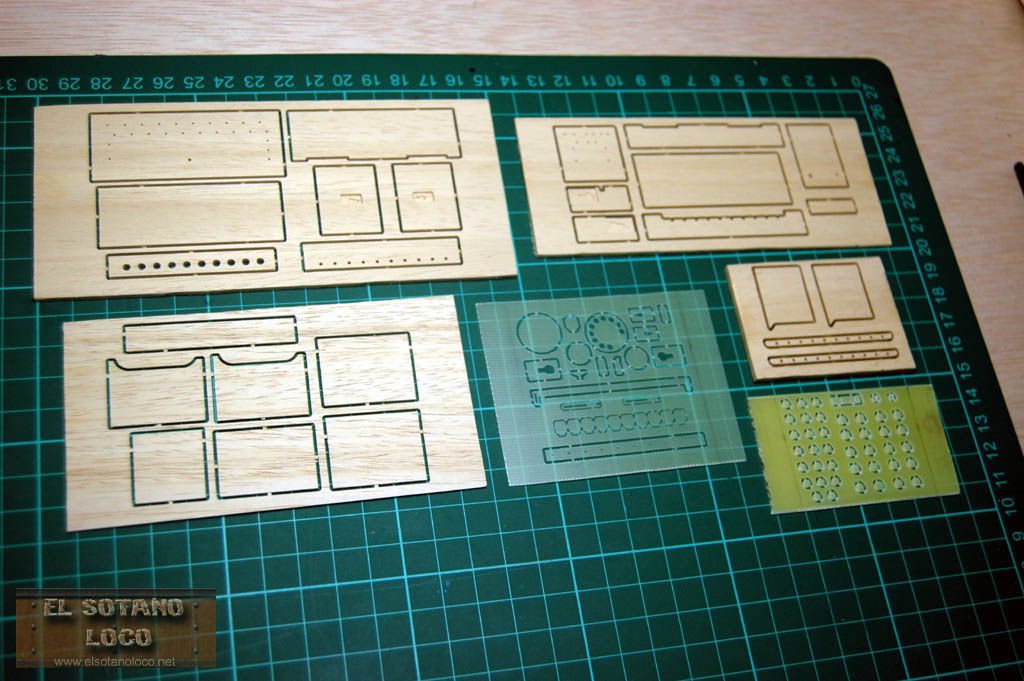

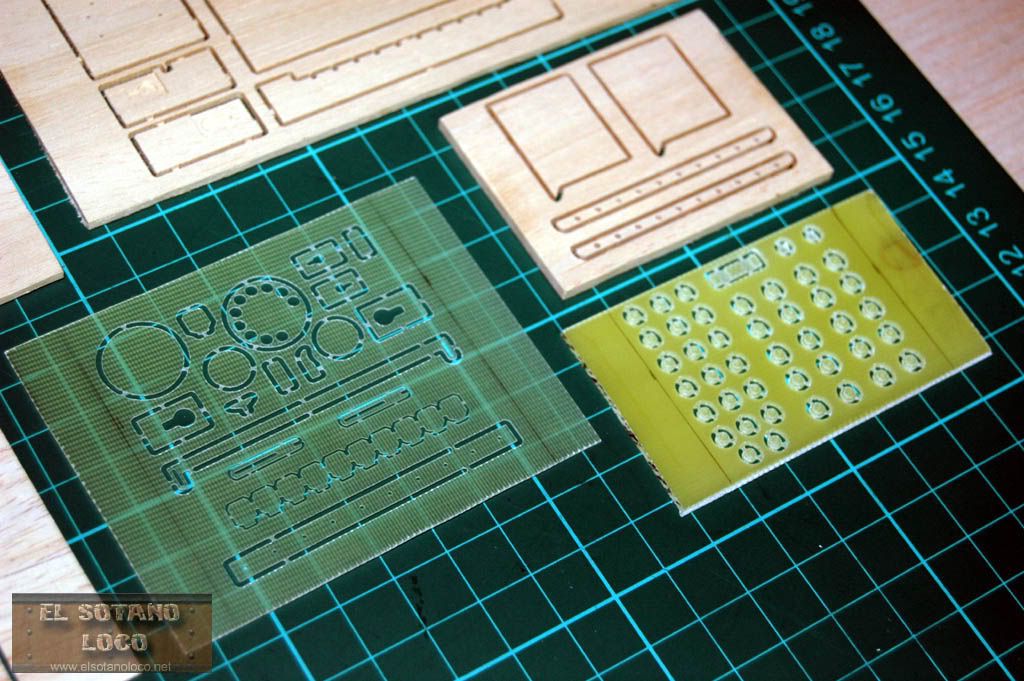

Today, I can show the first prototype of my Switchboard or unit of 10 lines (Kleiner KLAPPENSCHRANK 10fach), one of the most widely used in telephony and communications German World War II and that given the complexity of materials (the Wood is building everything by hand) and the number of terminals and cables you have, no house has major figures dared to bring to market conditions (remember the resin anchor bag in his series Dragon Models Cyber Hobby Communications Set 5 or that monstrosity that once sold goodstuff to Go and not like anything).

I'm not going to say anything that you do not know Telephony German World War II, and that the communication cable that was the greatest difficulty, pull the cables ... the other, connect phones or divert calls to the PBX ... etc ... was not over-complicated technology.

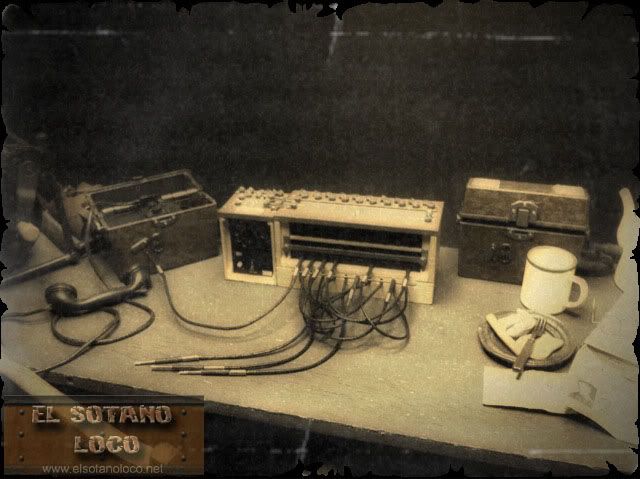

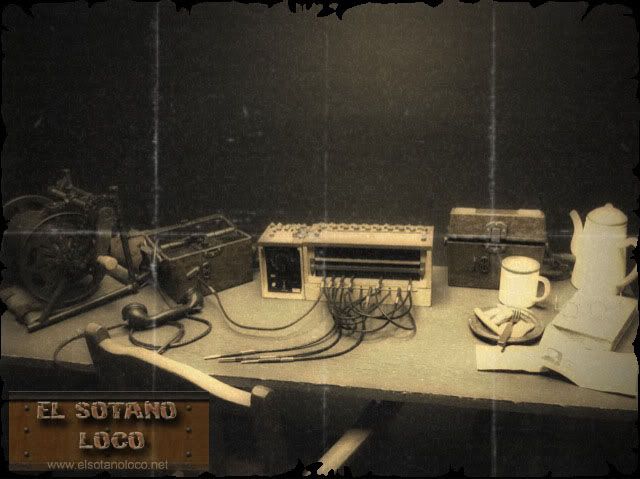

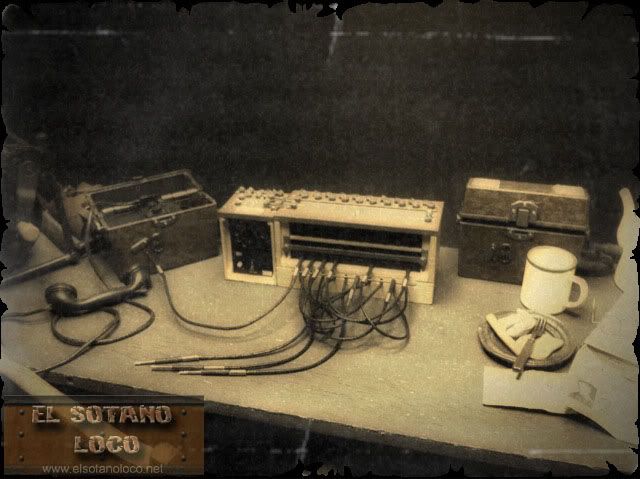

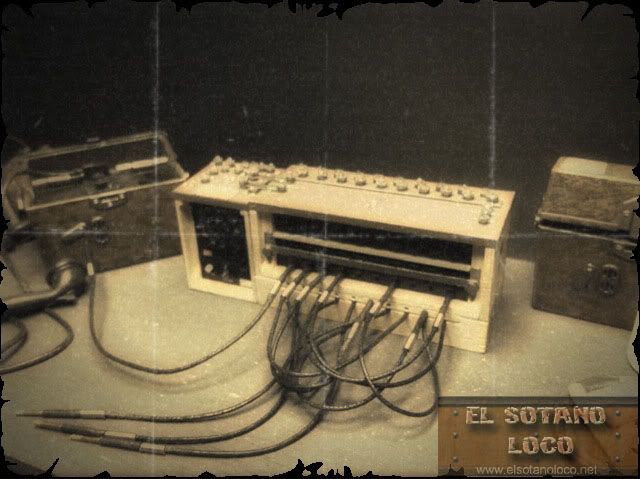

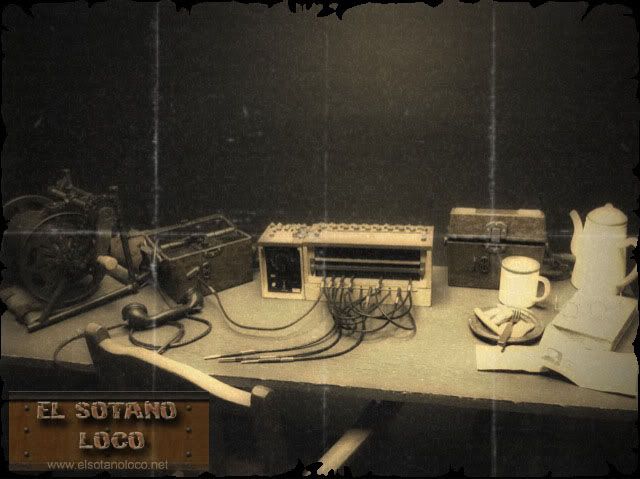

Have made a superdiorama wanted to prove it, but no time ...so I used the typical still life, which gives a little more grace to an item that is not too flashy for itself and although details still lacks polish I fix, this is well enough to prove it ...

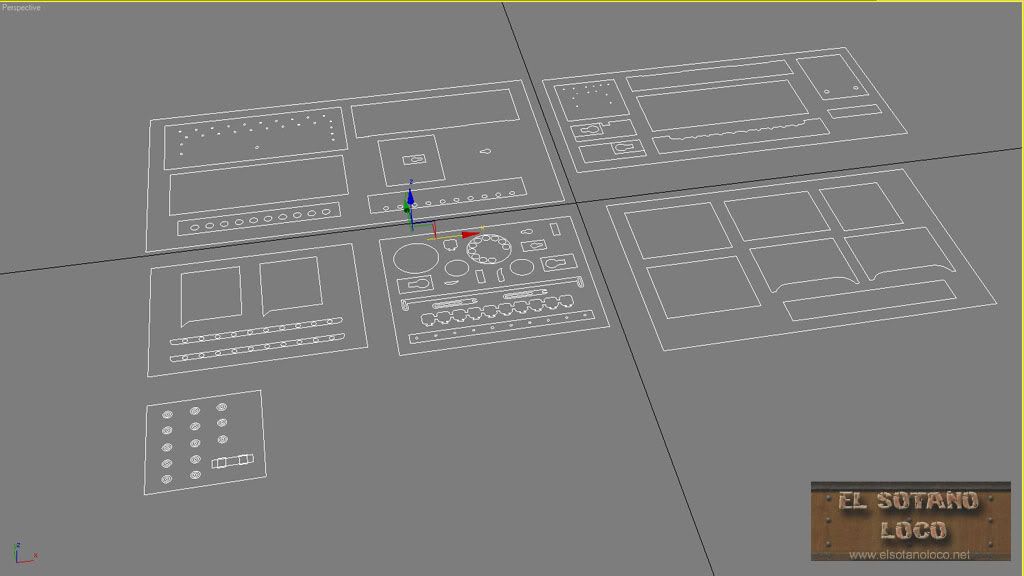

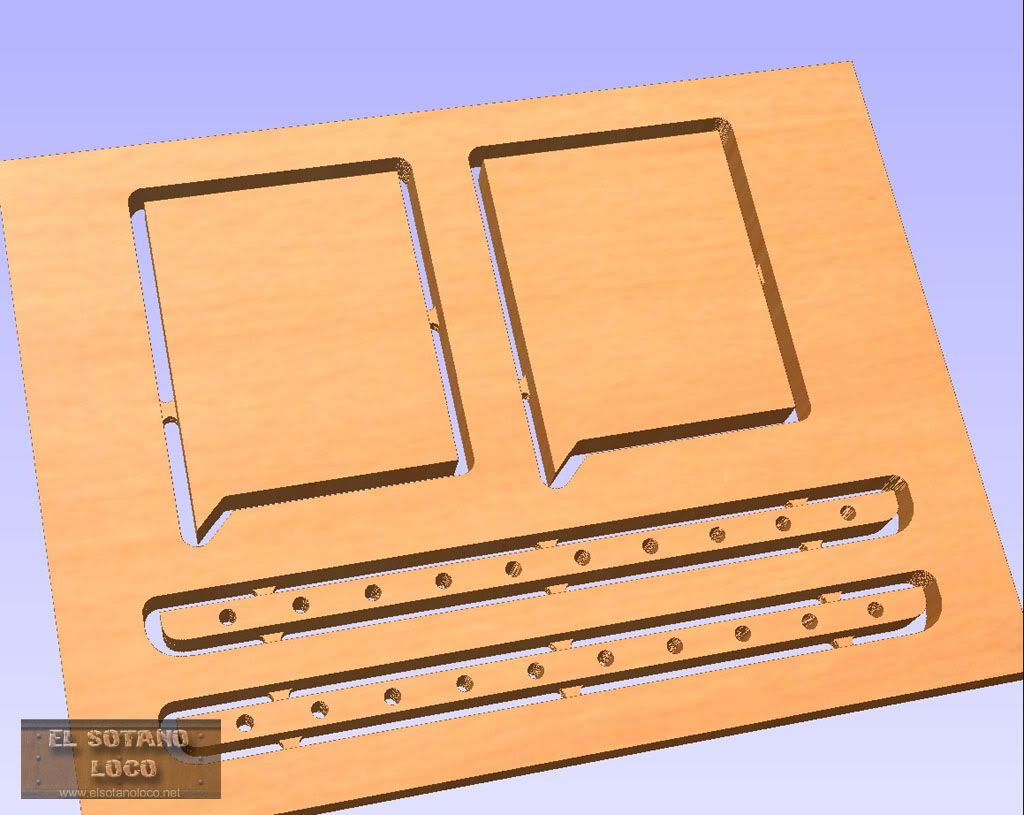

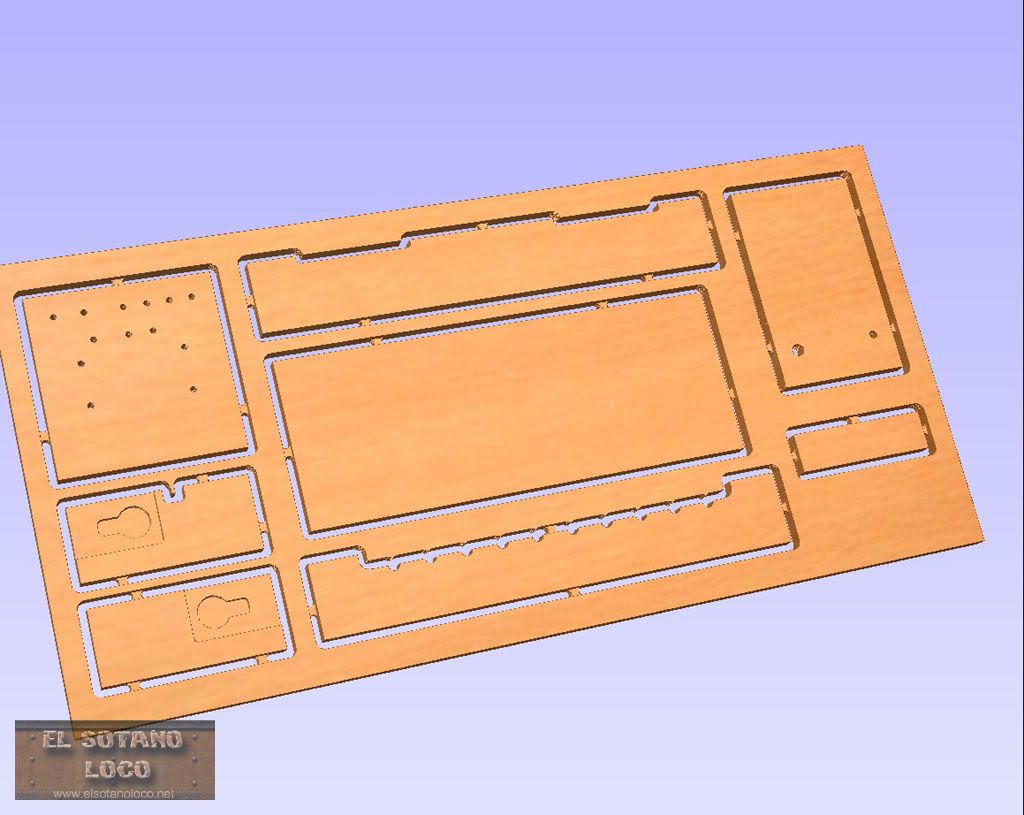

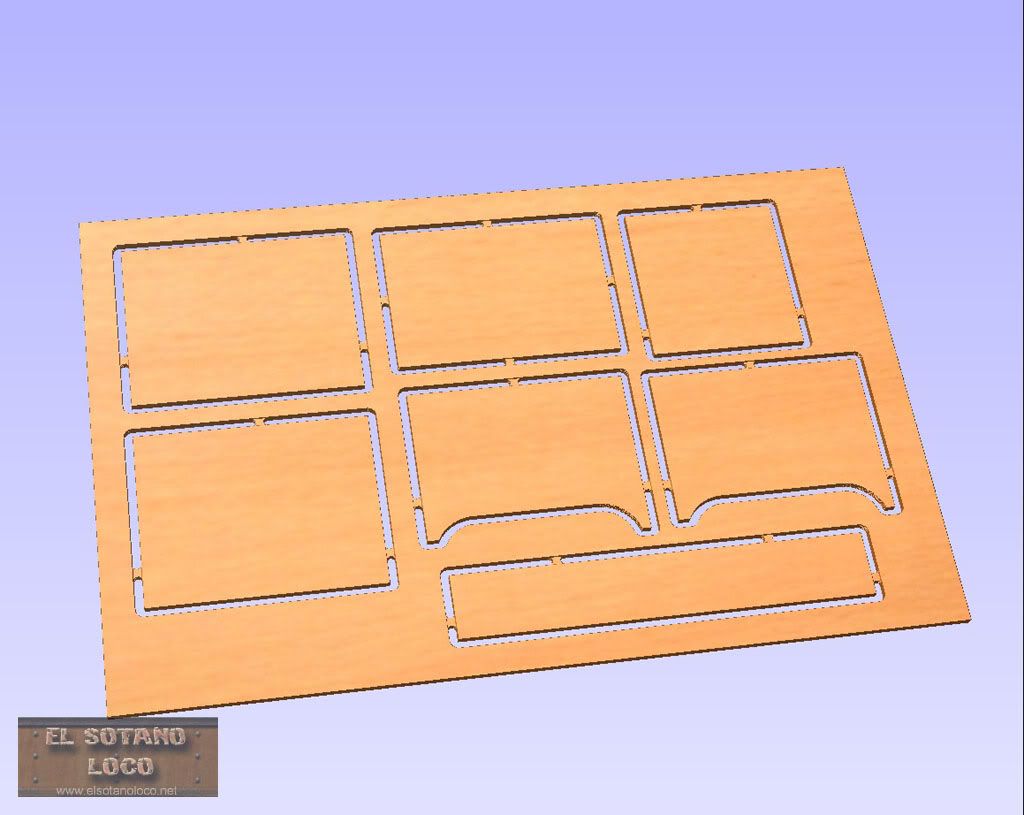

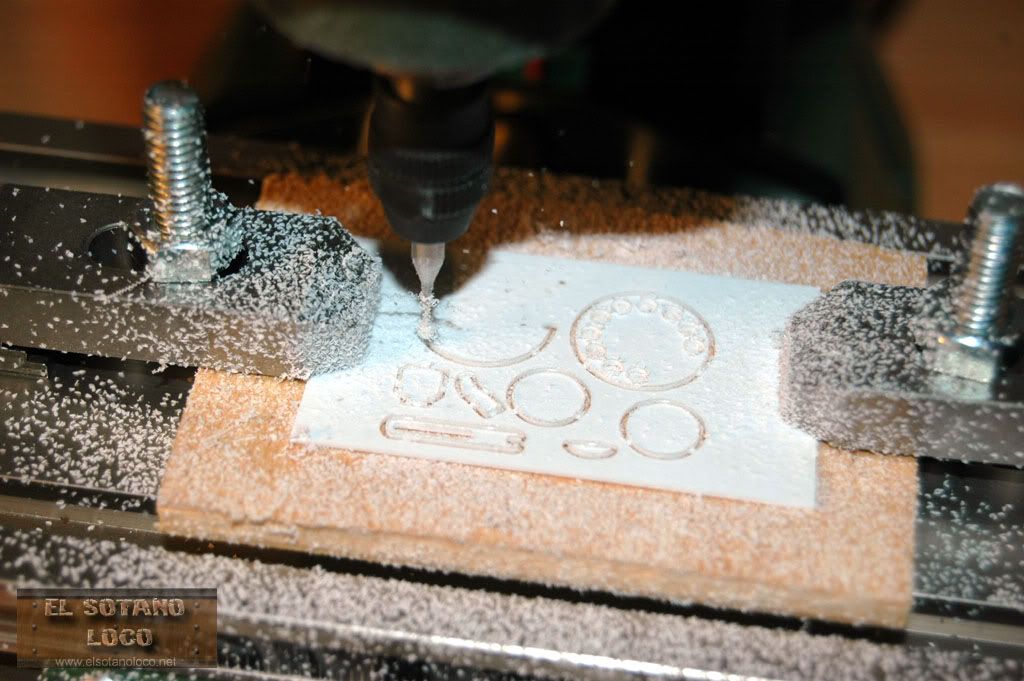

I will tell you later, as has been the manufacturing process, as it has come out of normal ... (Just to whet your appetite ... ... CNC 3D ...)

Well, we are more bored with nonsense and step show you the photos I've done, which is sure what more you are interested:

Photos:

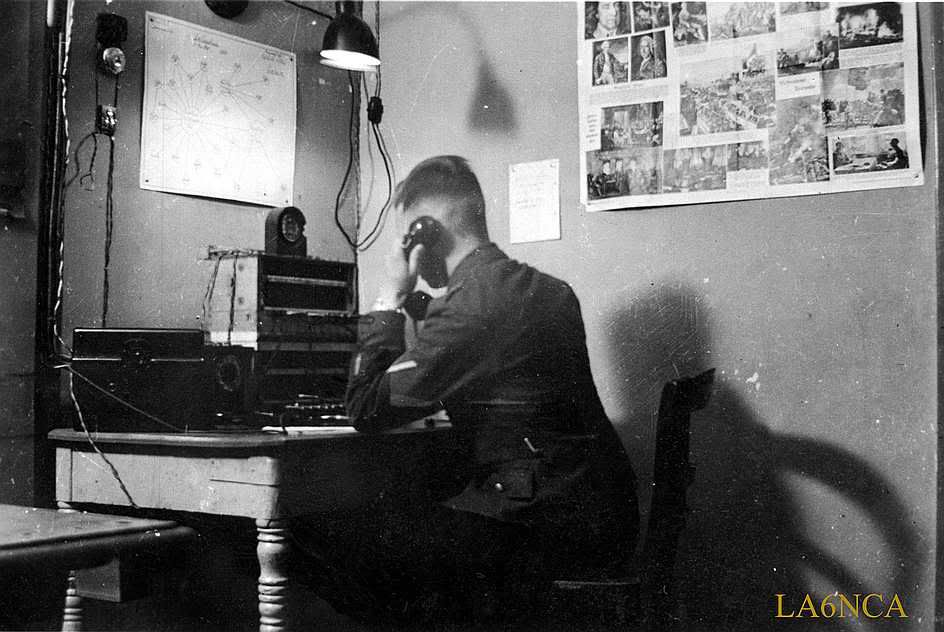

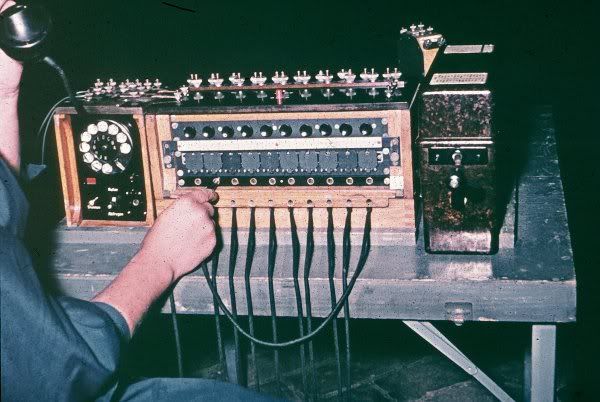

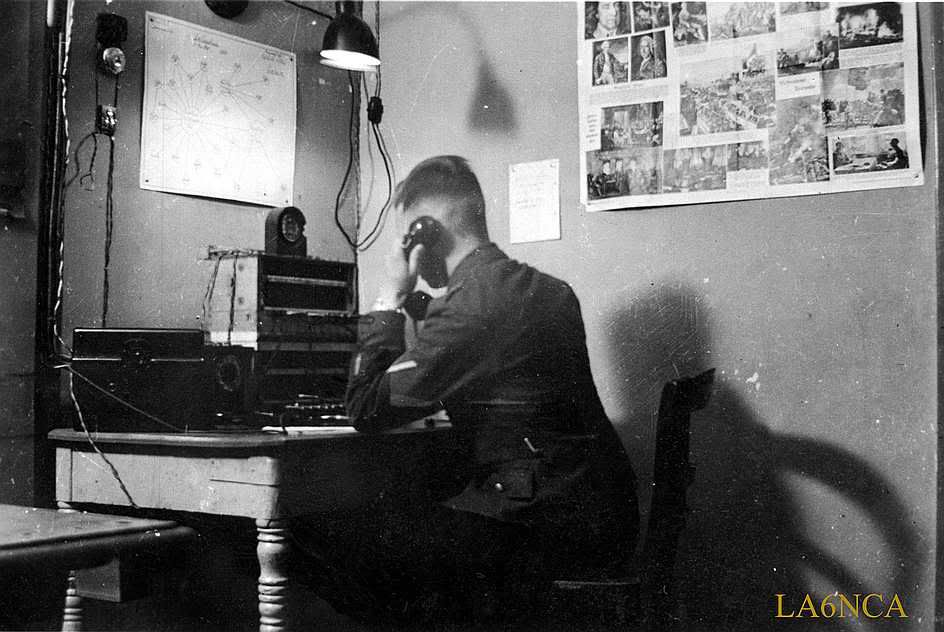

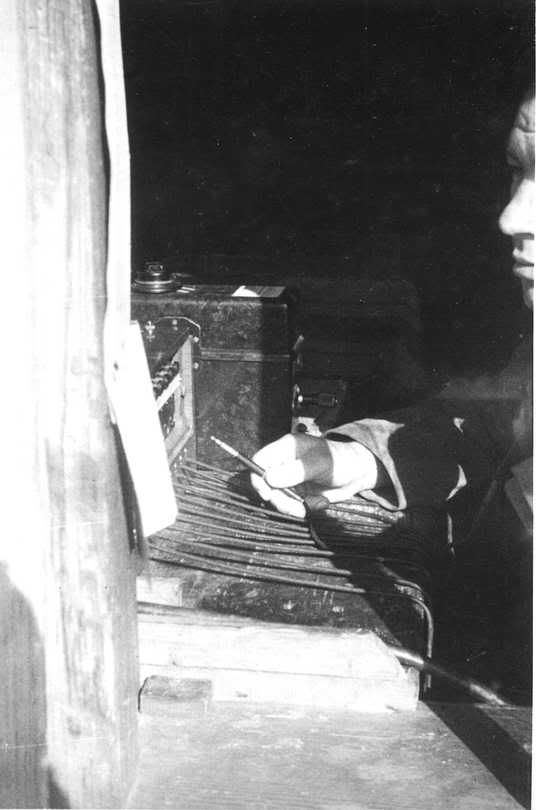

and the typical old photos that we like to ... (The last 2 were part of that superdiorama ...)

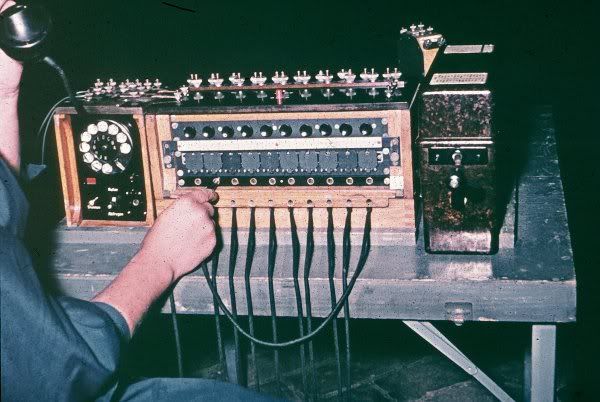

And the reference ones...

Hope you like ... soon you talk a little as has been their manufacturing process ...

Greetings to all

I want to present you my last creation...

Sorry for my English... this is an automatic translation, I dont know enough english to explain to you properly... if you do not understand something, please let me know... and I try to tell to you better...

Thanks in advance...

After several months of work, effort, learning new technologies, headaches and a lot of joy, now is the day I've waited and how much has been slow in coming.

Today, I can show the first prototype of my Switchboard or unit of 10 lines (Kleiner KLAPPENSCHRANK 10fach), one of the most widely used in telephony and communications German World War II and that given the complexity of materials (the Wood is building everything by hand) and the number of terminals and cables you have, no house has major figures dared to bring to market conditions (remember the resin anchor bag in his series Dragon Models Cyber Hobby Communications Set 5 or that monstrosity that once sold goodstuff to Go and not like anything).

I'm not going to say anything that you do not know Telephony German World War II, and that the communication cable that was the greatest difficulty, pull the cables ... the other, connect phones or divert calls to the PBX ... etc ... was not over-complicated technology.

Have made a superdiorama wanted to prove it, but no time ...so I used the typical still life, which gives a little more grace to an item that is not too flashy for itself and although details still lacks polish I fix, this is well enough to prove it ...

I will tell you later, as has been the manufacturing process, as it has come out of normal ... (Just to whet your appetite ... ... CNC 3D ...)

Well, we are more bored with nonsense and step show you the photos I've done, which is sure what more you are interested:

Photos:

and the typical old photos that we like to ... (The last 2 were part of that superdiorama ...)

And the reference ones...

Hope you like ... soon you talk a little as has been their manufacturing process ...

Greetings to all

))

))