Rolling Thunder Tech

Company Commander

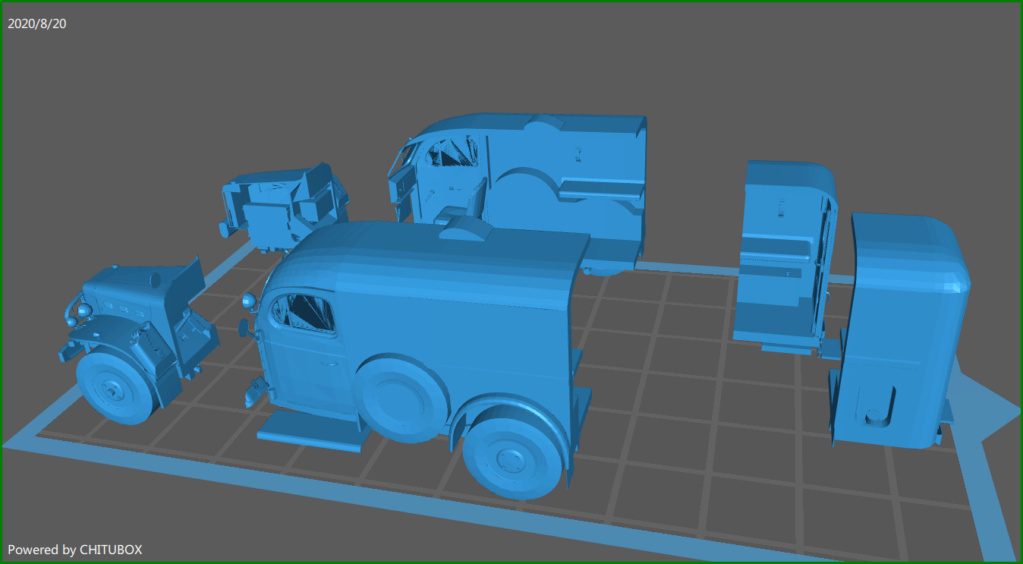

Been considering purchasing a small 3-D printer and have no experience with the process. Does anyone in the group have a 3-D printer and have advice for a beginner.

Leonard

RTT

Leonard

RTT

Dutchman, looks like I'll need to spend time to learn the 3-D programs. Looked up Fusion 360 and it appears to be free for one year, assuming I qualify and then there is a subscription cost. Is there another version of the program that is a free download without a time limit?

Leonard

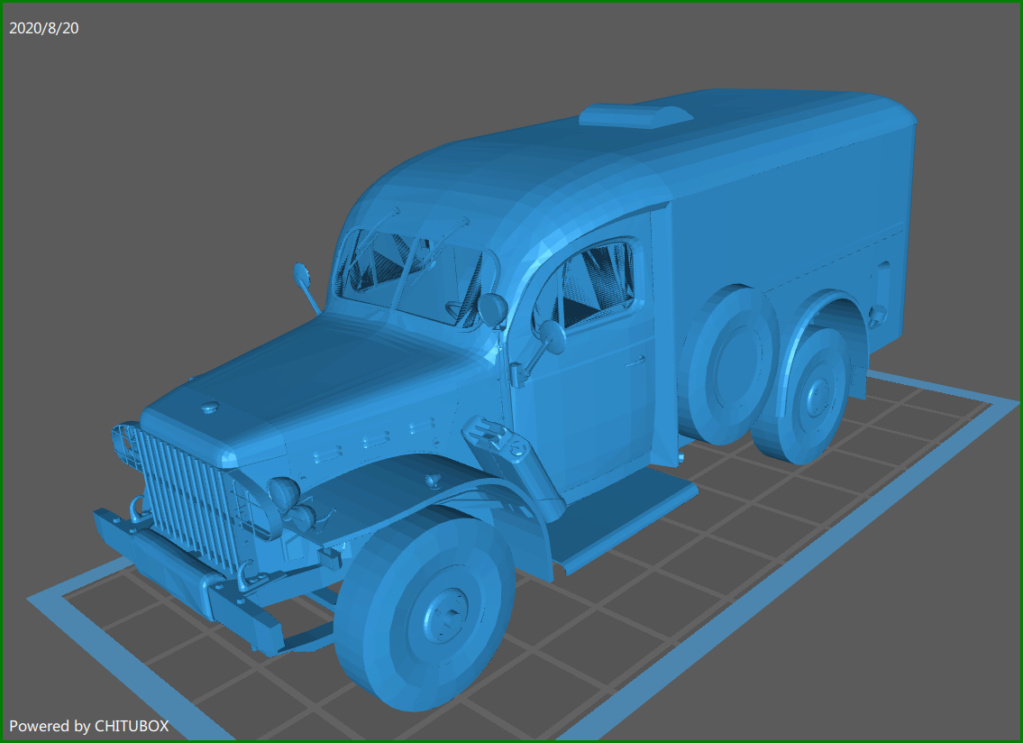

There is a learning curve for all the above especially if you are not an engineer or technical person. But none is hard with patience and practice. There are tons of YouTube videos for everything printing, so dive in!

There is a learning curve for all the above especially if you are not an engineer or technical person. But none is hard with patience and practice. There are tons of YouTube videos for everything printing, so dive in!It looks like there are quite a few different types of resins available for the Saturn. Which types of resins does the group recommend for different applications? I know that's a broad question.

Leonard

RTT

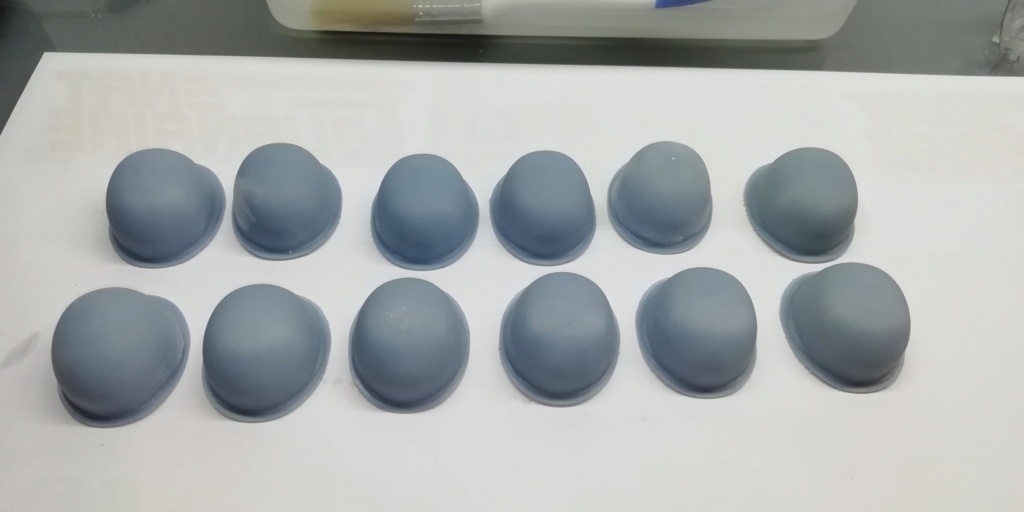

LOL, I've been designing the same cloverleaf caps.

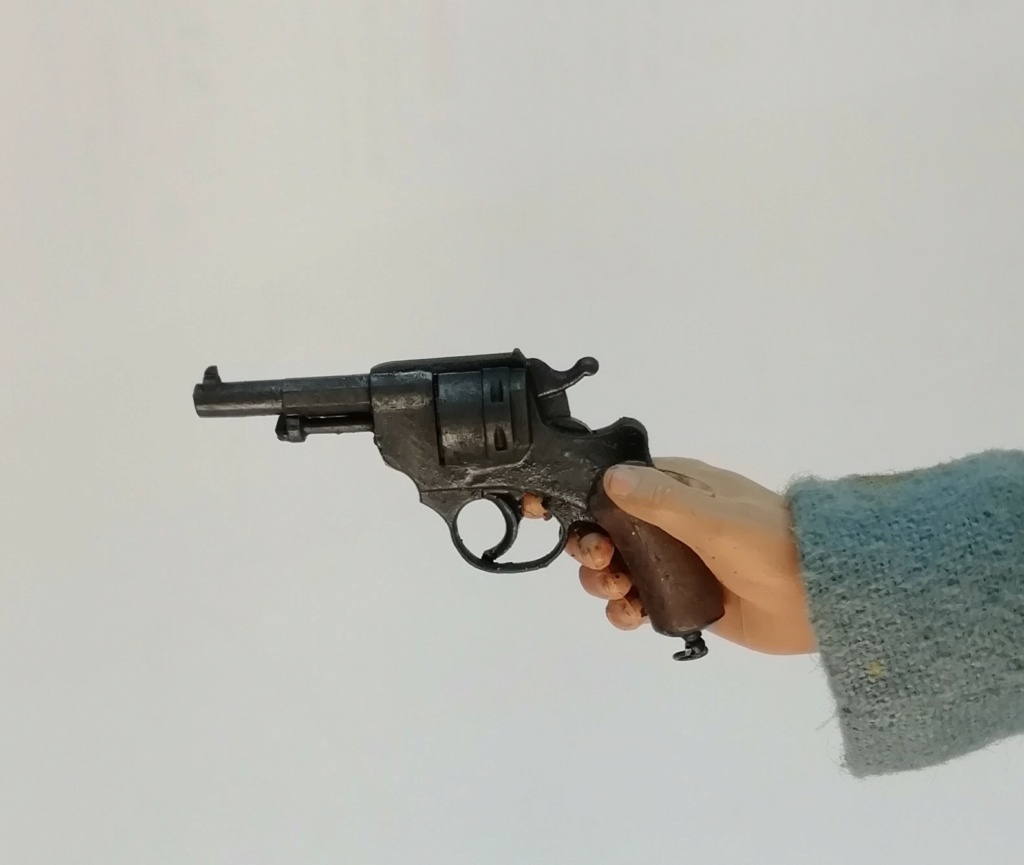

Shapeways is not cheap so I used them to print a master parts, from which I then casted resin copies.

Investing in your own 3d printer is worth it. My 3d material cost is a fraction of what Shapeways would charge me to print these cloverleaf caps. Ofcourse you need to invest money , but I have recuped that at least 10 fold sofar.

It's just like printing money...

Dudulle

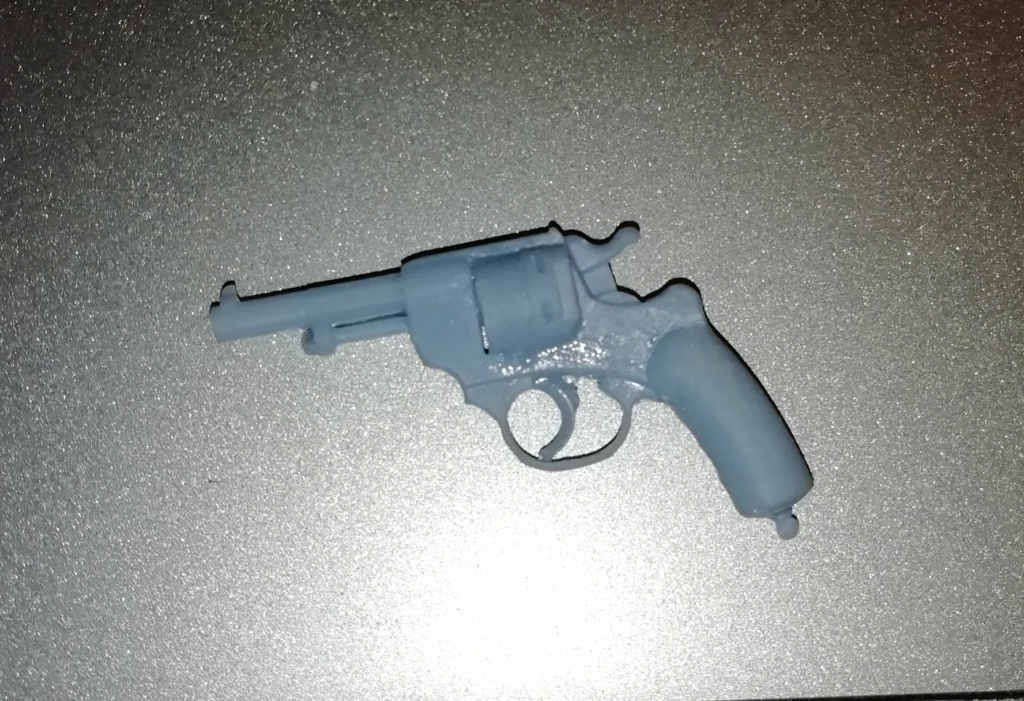

To show how much I don't know about 3-D printing. when you print the rifles, is it done horizontally or a vertical pull and are more than one done at a time?

thanks

Leonard